Engineering Composites 101.

- Outline Basics

- Materials

- Nomenclature

- Drawing Conventions

- Conclusions

COMPOSITE BASICS

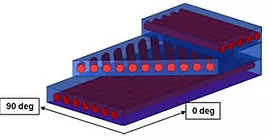

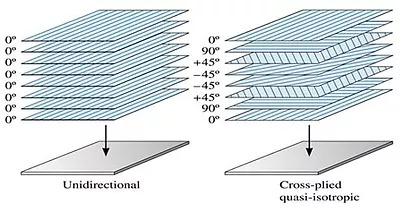

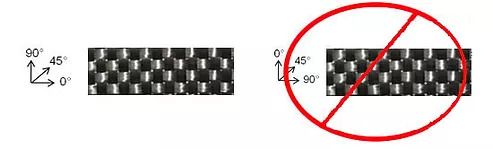

- Composites generally come in one of two forms: – Cloth or Fabric: a woven material with fibers usually running in both 0° and 90° orientations – Unidirectional fiber (a.k.a.: Uni or Tape) fibers all run in the same direction

- Laminates (multiple plies) are constructed from a combination of lamina(single ply)

- Sandwich panels are constructed from a combination of laminates, core, and typically a film adhesive

- CLOTH VERSUS UNIDIRECTIONAL

CLOTH

Advantages

- Drapes very well

- Easier to layup over complicated geometry

- Strength in two directions

- Bonds slightly better than uni

Disadvantages

- More expensive than uni

- Lower properties due to the fact fibers have to travel out-of-plane (over and under) due to the weaving process

UNIDIRECTIONAL

Advantages

- Better directional in-plane properties

- Less expensive than cloth

- Can easily tailor properties (i.e. strength, stiffness) in the needed direction

Disadvantages

- Hard to lay up over difficult geometry or complex curvature

- Requires careful planning to handle bearing loads

- May require longer lay up time to achieve desired thicknesses (uni is generally thinner than cloth)

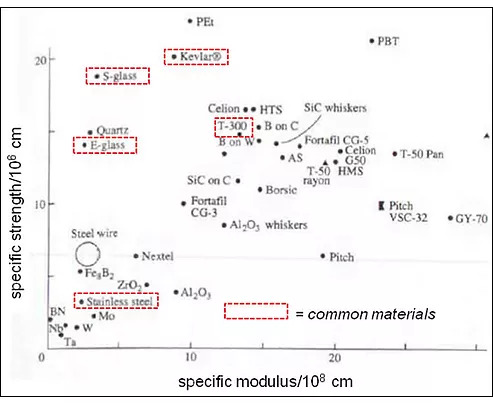

ROUGH ORDER OF MAGNITUDE FIBER COMPARISON

Specific Modulus is a materials property consisting of the elastic modulus per mass density of a material. The specific modulus is often important in aerospace applications in which maximum stiffeness for minimum weight is required.

Specific Strength is a material strength divided by its density. It is expressed in newton metres per kilogram, and is used for tensile strength as for compressive strength. It is sometimes known as the strength-to-weight ratio. Materials with very high specific strengths are widely used in aerospace applications where weight savings are more important than material costs.

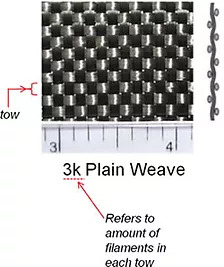

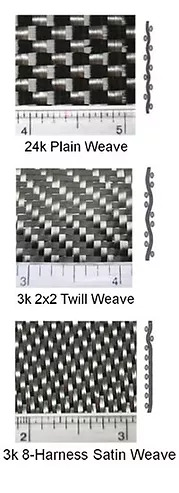

COMMON CLOTH WEAVES

There are many weaves available and these are just a few common examples

3k fiber is common, however 12k+ may be cheaper or have additional cosmetic appeal

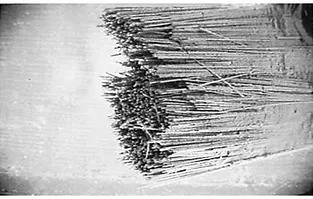

CARBON TOW MAGNIFICATION

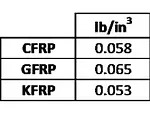

Typical densities for weight calculations

Design Trick: if adhesive is not being calculated separately add about 10% to the listed densities for the overall structure

BASIC LAMINATE STACKING

Laminate stacking and ply orientation is specific to the application.'

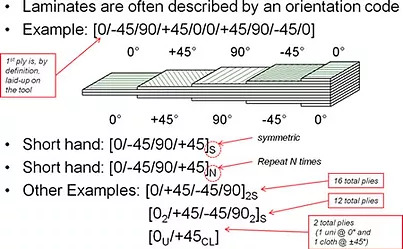

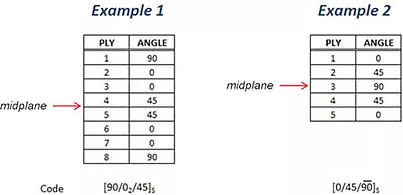

COMPOSITE LAYUP NOMENCLATURE

SYMMETRIC LAMINATES

Laminates possessing symmetry of lamina orientations about the geometric midplane

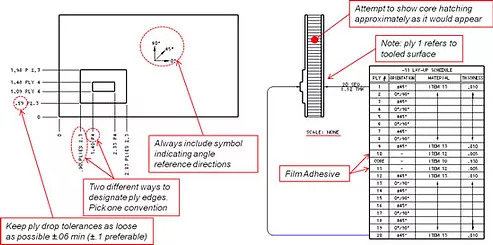

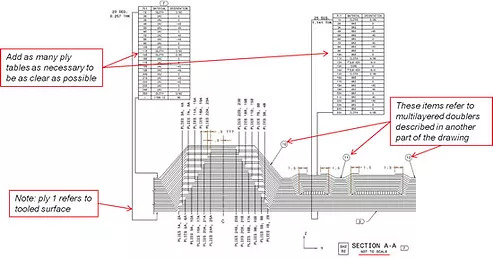

COMPOSITE DRAWING CONVENTIONS

The goal of composite drawings is to be as clear as possible – leave as little to misinterpretation as possible

Usually the 0° direction is along the long axis of the part

For simple lay-ups ply drops can be shown as below

More complicated lay-ups may require more detailed descriptions

CONCLUSION

Composite design and analysis requires a strong understanding of the material behavior, design practices, and manufacturing capabilities. The scope of this presentation scratches the surface of composites and their applications but we hope it sheds light on some of its mystery. Quartus Engineering Incorporated hopes you found this information useful in addressing your engineering challenges.