Medical & Life Science Product Development as a Services (PDaaS).

Quartus Engineering’s team specializes in designing and building complex subsystems and assemblies, with broad experience developing optical, mechatronics, fluidics, and electro-optical systems. Our flexible business model and subject matter expertise make Quartus an ideal engineering partner for new technology development. Let us help you accelerate your development schedule and solve your technical or programmatic challenges. Click below to learn more or reach out directly to see how we can help you bring your product to life.

CAPABILITIES

- Optical Systems

- Illumination and excitation sources

- Imaging and sensing

- Focusing assemblies (manual or automated)

- Beam management

- Collection and delivery assemblies

- Optoelectronics

- Single use devices

- Mechatronics (closed loop)

- Automated handling

- Precision motion control

- Robotics, AI and Vision Systems

- Structural, Optical, Thermal, CFD, Non-linear, Fatigue, Modal, Multi-Physics and composite analysis and simulation

- Technical support for regulatory submissions

- Class 10k Cleanrooms

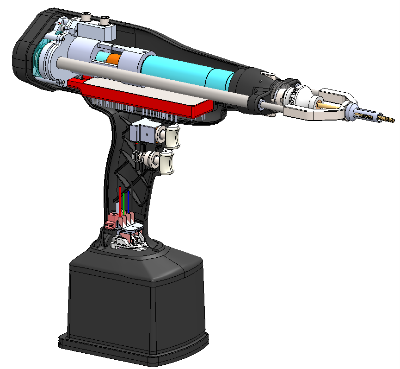

CASE STUDY: ORTHOPEDIC SURGICAL BONE DRILL

Quartus engineers designed and manufactured a revolutionary, FDA Certified smart drill for use in orthopedic surgery, enabling improved patient outcomes in the more common orthopedic surgical procedures. The first-of-its-kind design was able to reduce drill bit plunge and provide data for safe and accurate screw placement. Feedback sensors in the drill provide real-time data to the surgeon via an easy-to-read Graphical User Interface (GUI). Surgeons have visual confirmation of various measurements (torque, drill depth, and bone density) to guide their procedural decisions. Quartus provided the complete mechanical, industrial, electrical, software, and firmware design information for submission to the FDA for the 510(k) Premarket Notification.