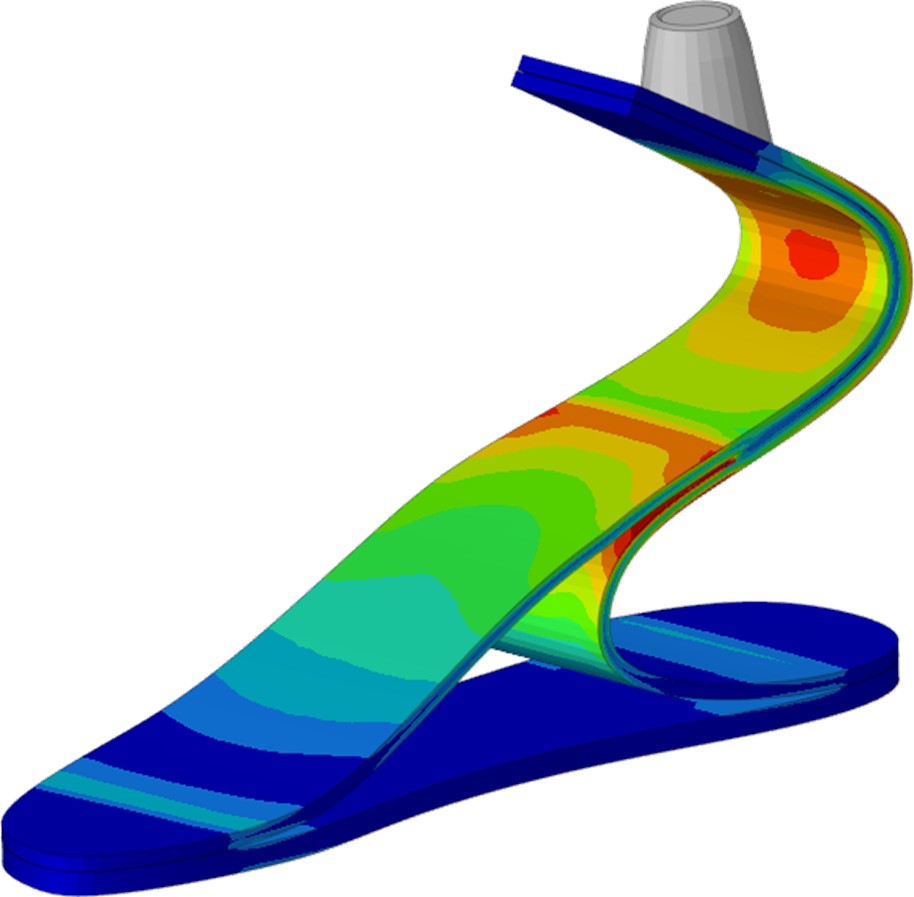

Prosthetics.

Developing a new wearable prosthetic? Quartus engineers can support you with design, analysis, simulation, test, and manufacturing process development. We employ advanced analysis and simulation techniques to accurately predict product performance and durability, allowing for design improvements to be implemented before a single prototype is built. Click below to learn more or contact us directly to review your unique project.

AREAS OF FOCUS:

- Upper and lower limbs

- Complex, multi-component prosthetics

- Metals, composites, polymers, elastomers and biological materials

- Computational modeling to simulate load paths, functionality, durability and comfort

CAPABILITIES

Structural, Thermal, Fluid Flow, Multi-Physics Analysis

- Design, assembly, integration, and product simulation

- Material Characterization

- ASME V&V 40 (Verification & Validation for Computational Modeling of Medical Devices)

Simulation Based Fatigue Response

- Peak loading simulation and correlation

- Tension and compression

- Infinite life characterizations

Assemblies

- Interfaces / tolerance analysis

Test

- Test plan development

- Tensile strength and shear test

- Post test model correlation