NASTRAN 101.

OUTLINE

Introduction

Introduction- File Structure

- Executive Control

- Bulk Data

- Element Types

- Element Examples

- Output Files

WHAT IS A FINITE ELEMENT 'SOLVER'?

- NASTRAN is one of many available finite element analysis (FEA) solvers

- Other solvers at Quartus: ABAQUS, ANSYS, LS-DYNA

- What does a solver do? (the short answer)

- User provides input in the form of a text file

- Solver reads the text file and performs analysis

- The solver generates output files with analysis results

- How does the user make the input text file?

- Models are created and input files exported using FEA pre/post processing software

- Various Pre/Post Processors available

- FEMAP, PATRAN, and Hypermesh commonly used with NASTRAN

WHAT IS NASTRAN?

Nastran is a powerful finite element analysis program that is used widely in the aerospace and automotive industries

- Industry standard finite element code originally developed for NASA by MSC (1960s)

- Today there are many flavors (or versions) of Nastran MSC, NX, etc.

Nastran at Quartus

- Primary program used for finite element analysis

- Used extensively to perform static, buckling, and dynamic analyses of structures

- Quartus has licenses for both NX/Nastran and MSC Nastran

- Largely the same (basic functionality)

- Some small differences and enhancements

WHAT UNITS DOES NASTRAN USE?

- NASTRAN does not have a defined unit system

- The user must be careful to maintain consistent units Units must be consistent such that units satisfy F= ma Examples for English and SI units are shown below:

Note: for English units (in, lbf, sec), the unit of mass is a ‘slinch’ (lbf-sec2/in), not a pound (lb). A slinch is the ‘inch version of a slug’. To convert from pounds to slinches you divide by the acceleration of gravity (386.1 in/sec^2)

WHAT IS AN INPUT FILE?

- At the most basic level, it’s nothing more than a formatted text file

- Defines the finite element model and all parameters necessary for analysis

- Nastran input files are often referred to as ‘decks’

- Origin of terminology comes from the time when the data was stored on actual punch cards and then fed into a machine that would read the ‘deck’ of cards.

- File extensions vary

- .dat usually used for input files

- .blk or .bdf usually used for included files

- Common text editors

- EditPad, UltraEdit, EmEditor, Emacs

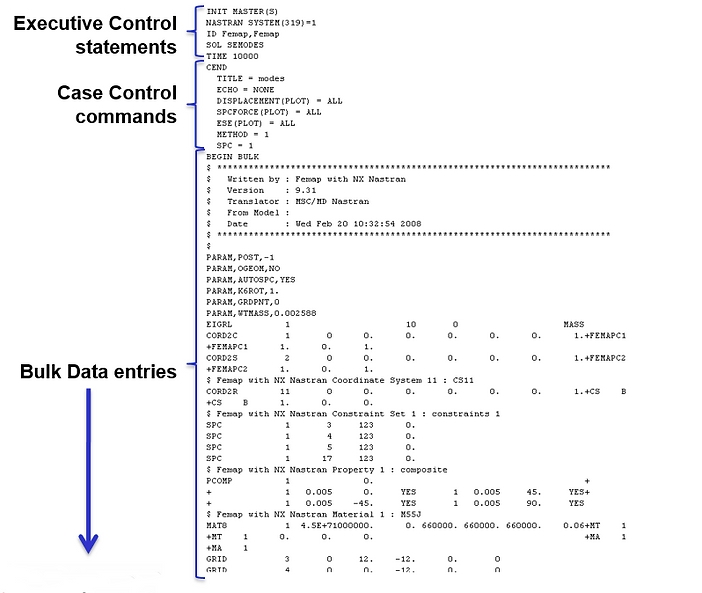

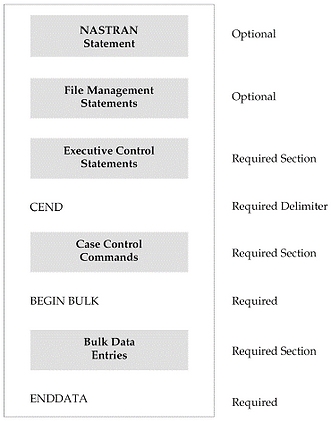

WHAT'S IN A NASTRAN INPUT DECK?

- Every deck can have 5 main sections

- Nastran statement

- File management statements (FMS)

- Executive control statements

- Case Control commands

- Bulk Data entries

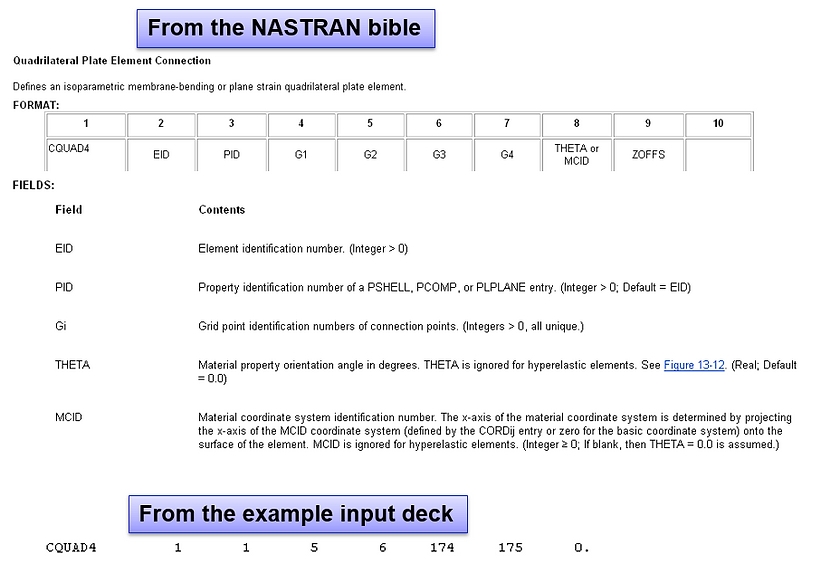

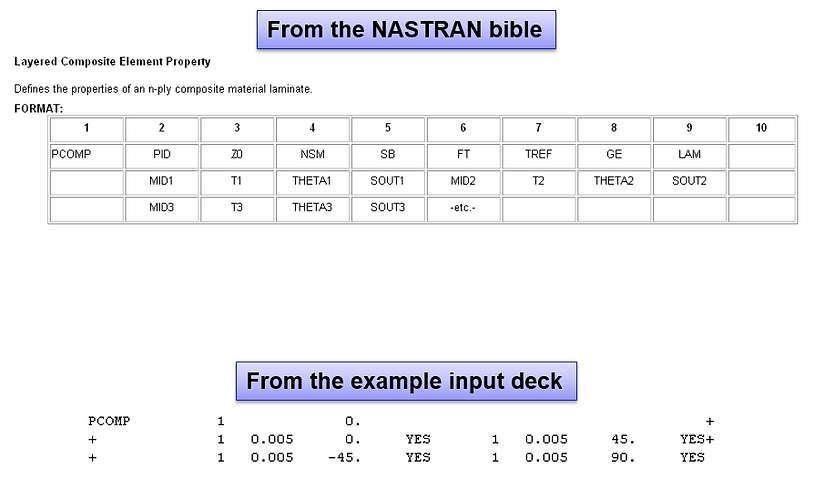

- The format and definition for all entries in the input deck can be found in the NASTRAN quick reference guides

- Commonly referred to as “the NASTRAN bible”

NASTRAN STATEMENT

- This section is optional

- This section is usually used only on large jobs where modifications are needed to more effectively run the job

- Used to change parameters for the solve

- BUFFSIZE

- DMP

- Scratch file setup

FILE MANAGEMENT SECTION

- This section is optional

- File management section is used primarily for saving databases and setting up restart files

- Restart a job from a previously analyzed job to reduce solve times

EXECUTIVE CONTROL SECTION

- Executive control section is required for all runs

- Includes:

- DMAP control Section (optional)

- ID (optional)

- Identification for the Job

- SOL (required)

- What type of solution? (linear static, buckling, modes, etc.)

- ECHO (optional)

- Control whether the executive control section is output to file

- Time (optional)

- Set up max CPU time

- DIAG (optional)

- Options for diagnostic information

SOL – COMMON SOLUTION SEQUENCES

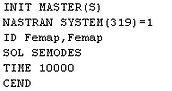

EXECUTIVE CONTROL – EXAMPLE INPUT DECK

Executive Control Section in the example deck:

This example deck performs a “normal modes” analysis.

SOL 103 = SOL SEMODES (either way will work)

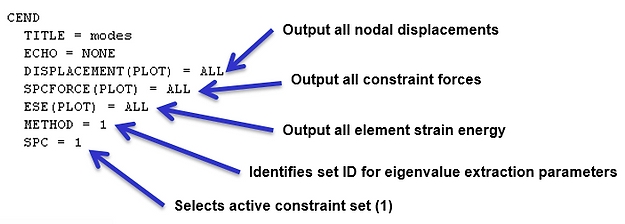

CASE CONTROL SECTION

- Case control section is required for all runs. Common features:

- Selection of constraint set (SPC)

- Selection of load set (LOAD)

- Selection of eigenvalue extraction parameters (METHOD)

- Used for buckling, modes, frequency response

- Output requests

MAIN PARTS OF BULK DATA

- Nodes

- Elements

- Coordinate Systems

- Properties

- Materials

- Constraints

- Analysis Parameters (PARAM, . . . )

BULK DATA: FORMAT

The bulk section is not order dependent. There are 3 options for format (can use each type within a single deck):

- Tab delimited

- Space delimited (default, short-field format = 8 spaces/field)

- Decks written from FEMAP and Hypermesh are space delimited

- Comma delimited

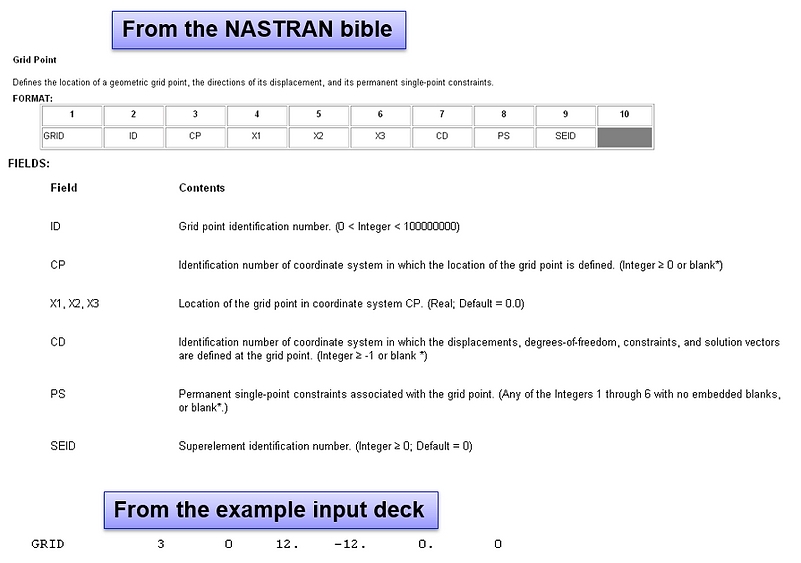

INPUT DECK NODE EXAMPLE

ELEMENT INFORMATION

5 major types of elements:

- 1D Elements: Bars, Beams, Rods

- 2D Elements: Plates, Laminates

- 3D Elements: Solids

- R-Type (rigids): RBE2, RBE3

- Connector /Other Elements: Springs, Lumped Masses

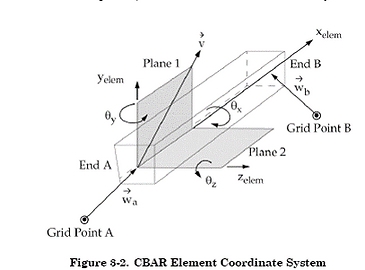

1D ELEMENTS

Common element types: beams, bars, rods

Common element types: beams, bars, rods

DOF

- Bars and Beams have axial, shear (2), bending (2), and torsion stiffness

- Bars and beams are basically the same

- Beams have more options

- Rods only have axial and torsion stiffness

2D ELEMENTS

Common element types: plates, laminates, membranes

DOF

- Plates and Laminates have in-plane (2), shear (in-plane and transverse), and bending stiffness

- Stiffness is associated with attached nodes for DOFs T1, T2, T3, R1, and R2

- No ‘drilling’ (R3) stiffness

- Membrane elements only have in-plane (normal) stiffness

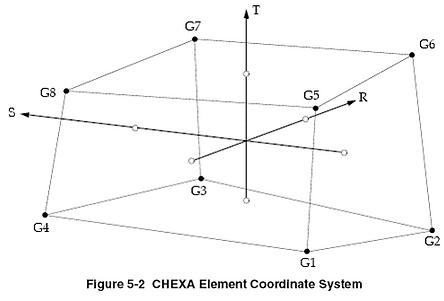

3D ELEMENTS

Common element types:

Common element types:

- Solids

- Shapes: bricks (CHEXA), wedges (CPENTA), tetrahedrons (CTETRA)

DOF

- 3D element nodes have associated stiffness in 3 DOF (T1, T2, and T3)

R-TYPE

RBE2

- Rigid element

- Infinitely stiff

- Adds stiffness to model

- No mass

RBE3

- Interpolation elements (constraint equations)

- Used to ‘average’ the responses of a number of nodes

- Does not add stiffness to model

Nodes on RBE's are either dependent or independent

- Important to be aware of dependencies

- Cannot apply boundary conditions to dependent nodes

- Nodes cannot be dependent on more than 1 RBE

CONNECTOR / OTHER ELEMENTS

Common element types: Springs, Lumped Masses

DOF

- Springs are normally used to connect coincident nodes

- Connect elements

- Recover forces

- Two main types of spring elements

- CELASi: connects only 1 DOF

- Multiple elements are required to connect more than 1 DOF

- CBUSH: can connect 1-6 DOF

- Newer, more versatile spring element

- Lumped masses are used to model mass and inertia at a node and have no stiffness

- CONMi

INPUT DECK ELEMENT EXAMPLE

HINGING/PINNING

Common problem when elements with different DOF’s are connected

- Plates to Solids

- Beams and Bars to Plates or Solids

COORDINATE SYSTEMS

- Coordinate systems are used to define node locations and output

- Nodes can have different definition and output coordinate systems

- Coordinate system zero is the default rectangular system located at (0,0,0)

- Rectangular, cylindrical, and spherical coordinate systems can be used in Nastran

PROPERTIES

Properties define the characteristics of the elements

- Plate thickness, beam cross-section, spring stiffness, etc.

- Properties reference materials

- Materials are defined on separate cards

Each element type has a different property

- Some elements don’t use a property but instead input the information directly on the element card

EXAMPLE PROPERTY IN THE INPUT DECK

EXAMPLE MATERIAL IN THE INPUT DECK

NASTRAN FILES: COMMON OUTPUT FILES

- .op2

- Output2 File: binary file including results for FEMAP

- Most commonly used file for output

- .pch

- Punch File: results in tabulated text format

- .f06

- Text file with results from analysis along with diagnostic messages

- Can be read by FEMAP or processed by various custom programs

- .f04

- Text file containing run information; database file info, module execution summary, etc. (highly detailed log)

- .log

- Text file with general information; control file info, run time, licensing information, etc.