Medical Implants.

Quartus engineers have years of experience designing, analyzing, and testing medical devices throughout the whole body, including performing one-off simulations, assisting with submission materials and complex design-of-experiments. From single-use products, to wearable products, to permanent implants, the Quartus team has years of experience in areas such as:

- Cardiac implantable and disposable devices

- Orthopedic implants and tools

- Otolaryngology devices

- Single-use, and multi-use test equipment

- Prosthetics

CAPABILITIES

Structural, Thermal, Fluid Flow, Multiphysics

- Design, assembly, integration, and product simulation

- ASME V&V 40 (Verification & Validation in Computational Modeling of Medical Devices)

- In vitro/vivo modeling

- Fluid-structure interface modeling for full device characterization

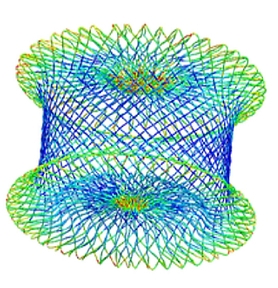

Simulation Based Acute and Fatigue Response

- Radial force simulations and correlations

- Infinite life characterization

- Material characterization and calibration

- Metallic, ceramic, and biological materials

Nitinol Subject Matter Experts

- Nitinol device design

- Shape setting optimization

- Training and educational services available

contact nitinol wire braid

CASE STUDY

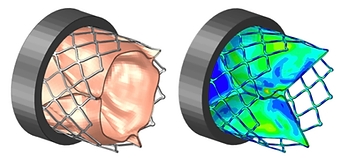

Fatigue & Hemodynamic Analysis of Aortic Heart Valve

- Fully-coupled fluid-structure analysis using StarCCM & Abaqus

- Fluid dynamically deflects leaflet tissue, imparting physiological loads on stent

- Elasto-plastic, superelastic, & custom anisotropic hyperelastic material models

- Full-field stresses & strains on stent, leaflets, & fluid

Quartus aids the design process through:

- Manufacturing & fatigue analysis of the stent frame

- Allows for rapid design iterations

- Nitinol, stainless steel, titanium; tube or braid

- Hemodynamic analysis

- Calculation of pressure drop, stagnation, hemolysis, etc.

- Trade studies on geometric & manufacturing parameters

- Regulatory submission analyses

- Verification & validation

- Qualitative & quantitative comparison to in-vitro testing

- Convergence & sensitivity studies